Neodymium Magnetic System

RUBBER COATING MAGNETS/PLASTIC

Rubber or plastic Magnetic Systems combine the strength of Neodymium with the protection given by the coating that covers the magnet.

The three series we propose have characteristics that make them suitable for different applications, according to the required fastening system:

-

SM35: Rubber disc with threaded hole on the non-magnetic side. Neodymium magnets of both poles on the same face;

-

SM37: rubber or plastic shell with through-hole;

-

SM56: Rubber shell with through countersunk hole; magnetic side on the countersink.

The use of rubber for the outer shell offers several advantages: from greater grip on very smooth metal surfaces (especially if supported vertically) to a reduced risk of scratches or dents when the magnet adheres to the metal part.

Although the magnets are completely contained inside the shell, these types of magnets are NOT suitable for prolonged use underwater or in very humid environments, as they are not watertight. For the aforementioned uses, we have developed the SM39 series, which can be consulted by clicking on the blue code.

Contact us directly to get a quick feedback on prices and availability.

You can view and download the technical drawings of each product by clicking on the respective code, highlighted in blue.

All measures are in millimeters (mm).

BLIND THREADED HOLE

.png)

| CODE | D | H | HOLE (F) | STRENGTH KG |

|---|---|---|---|---|

| SM35.35GO00.308M4GOM | 30 | 8 | M4 | 8 |

| SM35.35GO00.348M4GOM | 34 | 8 | M4 | 8,20 |

| SM35.35GO00.436M4GOM | 43 | 6 | M4 | 8,50 |

| SM35.35GO00.668M6GOM | 66 | 8,5 | M6 | 20 |

| SM35.35GO00.8888GOMMA | 88 | 8 | M8 | 42 |

CYLINDRICAL HOLE

(1).png)

| CODE | D | H | HEIGHT HOLE | STRENGTH KG |

|---|---|---|---|---|

| SM37.35GO00.30066 | 31 | 6 | D6 | 6 |

| SM37.35PL00.3496 PLASTICA | 34 | 9 | D6 | 11 |

COUNTERSUNK HOLE

.png)

| CODE | D | H | HEIGHT HOLE | STRENGTH KG |

|---|---|---|---|---|

| SM56.35GOSV.2264.5 | 22 | 6 | 4,5 | 4,50 |

| SM56.35GOSV.3484.5 | 34 | 8 | 4,5 | 7,80 |

| SM56.35GOSV.4364.5 | 43 | 6 | 4,5 | 11,40 |

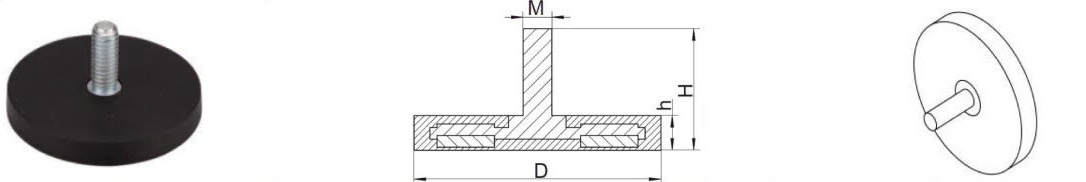

THREADED ROD

| CODE | D | H | THREAD TYPE | STRENGTH KG |

|---|---|---|---|---|

| SM57.35GO00.226M4 | 22 | 6 | M4X6,5 | 5 |

| SM57.35GO00.436M6 | 43 | 6 | M6X15 | 8 |

| SM57.35GO00.668M8 | 66 | 8 | M8X15 | 20 |

| SM57.35GO00.888.5M8 | 88 | 8,5 | M8X16 | 42 |

The maximum standard operating temperature is 80 °C.

On request, we can supply magnets capable of operating at higher temperatures, as indicated in the Materials Table.

Many of these sizes are also available in other variants, with different coatings and degrees of magnetization.

The force values given in the tables are the result of dynamometric tests performed with a 10 mm thick iron plate.

Any variations from this standard in the use may change the actual performance of the magnet.

|

It is always recommended to perform specific tests according to your application. |

Request information

For any request or information fill out this form, we will reply as soon as possible.

Fields marked with an asterisk (*) are required.